In the field of urban underground space development, Urban Utility Tunnel Drilling serves as a core technology in modern municipal construction, fundamentally transforming traditional pipeline installation methods. With its trenchless and high-precision advantages, Horizontal Directional Drilling (HDD) technology has become the preferred method for Urban Utility Tunnel Drilling. This article systematically analyzes how HDD provides innovative solutions for Urban Utility Tunnel Drilling.

I. Technical Challenges of Urban Utility Tunnel DrillingUrban Utility Tunnel Drilling faces three major challenges:

1. Spatial Constraints: Requires precise navigation through dense building clusters

2. Complex Geology: Deals with unstable strata like silt and sand layers

3. Environmental Requirements: Minimizes construction impact on surrounding areas

HDD addresses these challenges in Urban Utility Tunnel Drilling through:

1. 3D guidance systems (±10cm positioning accuracy)

2. Mud retaining wall technology (<3% borehole collapse rate)

3. Modular design (minimum turning radius of 15m)

II. Five Advantages of HDD in Urban Utility Tunnel Drilling1.

1. Trenchless Construction

Reduces road excavation by 80% compared to traditional methods

2. Curved Drilling Capability

Enables "S-shaped" trajectory design to bypass underground obstacles

3. Large-Diameter Installation

Supports pipe pulling up to DN1200

4. Precise Depth Control

Achieves elevation errors <0.5% with gyroscopic positioning

5. Cost Optimization

Saves over 30% compared to open-cut methods

III. Key Construction Processes for Urban Utility Tunnel Drilling

1. Preliminary Survey

Uses ground-penetrating radar to detect obstacles within 3m depth

2. Trajectory Design

BIM technology simulates optimal drilling paths

3. Pilot Drilling

Real-time correction with wireless measurement systems

4. Reaming

Gradual expansion from φ200mm to target diameter

5. Pipe Pulling

Drag-reducing mud technology ensures smooth completion

IV. Hengwang Group HWF50 Horizontal Directional Drill

1. Product Overview

The HWF50 Horizontal Directional Drill is specifically developed for Urban Utility Tunnel Drilling, featuring:

Color Scheme: Yellow and black main body with rubber tracks

Operating Environment: Suitable for outdoor sandy/soil terrain

2. Core Features

(1) Power System

① Yanmar Stage IV engine (46.2kW)

② Fuel capacity: 72L

(1) Mobility & Design

① Rubber tracks (<35kPa ground pressure)

② Compact dimensions: 3880×1330×1800mm

③ Operating weight: 3450kg

(1) Smart Operation

① Automatic hydraulic anchoring

② Single-operator control with drill rod box (44×φ42mm rods)

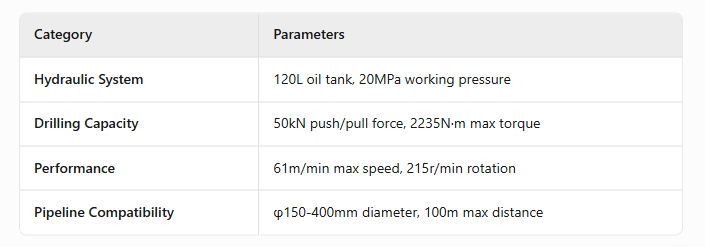

3. Technical Specifications

4. Application Advantages

(1) Achieves 25m/day efficiency in Urban Utility Tunnel Drilling

(2) 60% lower failure rates than industry standards

(3) Ideal for confined urban construction spaces

Conclusion

As smart city development progresses, Urban Utility Tunnel Drilling will see broader applications. Hengwang Group continues to innovate HDD technology to deliver efficient underground solutions globally.

Author: Hengwang International Marketing Center | Serving infrastructure projects in 30+ countries.

Road Leveling Bulldozer: The Core Guarantee for Efficient Road Construction

Road Leveling Bulldozer: The Core Guarantee for Efficient Road Construction

Off-Road Forklifts_ A Powerful Assistant for Complex Field Operations

Off-Road Forklifts_ A Powerful Assistant for Complex Field Operations

High-Load Off-Road Forklift: A Powerful Tool for Heavy-Duty Operations in Complex Environments

High-Load Off-Road Forklift: A Powerful Tool for Heavy-Duty Operations in Complex Environments